Electroplating Factors You Want to Know

Essential Elements

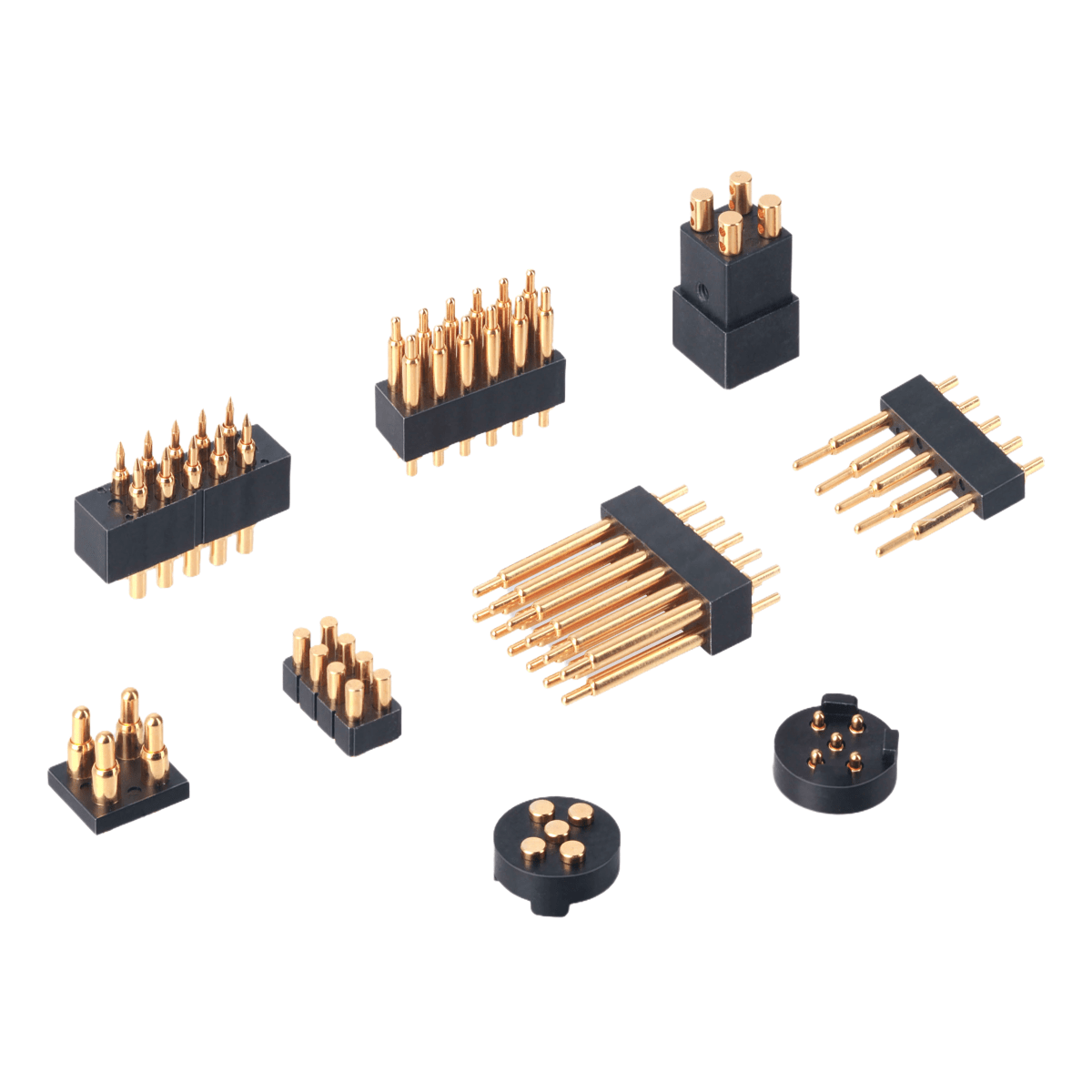

- Cathode: The object to be plated, such as various connector terminals.

- Anode: If soluble, it’s the metal to be plated; if insoluble, it’s usually precious metals like platinum or iridium oxide.

- Electroplating Solution: Contains the metal ions to be plated.

- Electroplating Tank: Used to store the electroplating solution, considering strength, corrosion resistance, and temperature resistance.

- Rectifier: Provides the DC power source for the electroplating process

Purpose of Electroplating

- Copper Plating: Enhances adhesion and corrosion resistance.

- Nickel Plating: Improves corrosion resistance.

- Gold Plating: Enhances electrical contact resistance and signal transmission.

- Palladium-Nickel Plating: Improves electrical contact resistance, signal transmission, and has better wear resistance than gold.

- Tin-Lead Plating: Enhances solderability.

Composition of Electroplating Solution

- Pure Water: Impurities should be below 5ppm.

- Metal Salts: Provide the metal ions for plating.

- Anode Dissolution Additives: Balance the anode dissolution rate.

- Conductive Salts: Improve the conductivity of the solution.

- Additives: Buffer agents, brighteners, leveling agents, softeners, wetting agents, and inhibitors.

Electroplating Conditions

- Current Density: The current per unit plating area. Higher current density results in thicker films but can cause burning or rough surfaces if too high.

- Plating Position: The position of the object in the solution affects film thickness distribution.

- Stirring Conditions: Better stirring improves electroplating efficiency.

- Current Waveform: Better filtration leads to more uniform plating structure.

- Solution Temperature: Gold plating 50-60°C, nickel plating 50-60°C, tin-lead plating 18-22°C, palladium-nickel plating 45-55°C.

- Solution pH: Gold plating 4.0-4.8, nickel plating 3.8-4.4, palladium-nickel plating 8.0-8.5.

- Solution Specific Gravity: Lower specific gravity indicates poorer conductivity and lower efficiency.

Electroplating Thickness

- Tin-Lead Alloy Plating: For soldering, typically 100-150 microinches.

- Nickel Plating: Commonly used as a base layer in electronics, usually over 50 microinches.

- Gold Plating: Due to its high cost, thickness is chosen based on practical use, cost, and environmental resistance, typically over 50 microinches for severe corrosion tests.

Inspection of Plating Layers

- Appearance Inspection: Visual inspection or magnifying glass (4-10x).

- Thickness Measurement: X-ray fluorescence thickness gauge.

- Adhesion Test: Bend test or tape test.

- Solderability Test: Dip test, requiring over 95% uniform and smooth solder coverage.

- Steam Aging Test: Check for discoloration or corrosion spots.

- Anti-discoloration Test: Oven baking test.

- Corrosion Resistance Test: Salt spray, nitric acid, sulfur dioxide, hydrogen sulfide tests.

Leave a Reply