Connectors: The Backbone of Modern Electronics

Connectors are essential components in electronic devices, facilitating the transmission of current, signals, and data. Despite their varied structures and forms based on application fields, usage environments, and working frequencies, connectors’ core performance can be classified into three main categories: electrical performance, mechanical performance, and environmental performance.

In this article, we’ll focus on electrical performance, discussing its importance and key indicators.

Electrical Performance

Electrical performance ensures connectors can operate stably and safely in various electrical environments. Here are the common electrical performance indicators:

- Contact ResistanceContact resistance is the resistance created at the contact surface between two conductors. It directly affects the efficiency of current flow and signal transmission. Lower contact resistance is preferred as it reduces heat generation and circuit loss, ensuring safer and more efficient operation.

- Insulation ResistanceInsulation resistance measures the ability of an insulator to prevent leakage current. A higher resistance value indicates better performance. This is typically measured in megohms (MΩ) and is crucial for ensuring connectors’ insulation properties.Example: For M12 circular connectors, the insulation resistance should be tested at 500V ± 15V DC, and it should not be less than 100MΩ.

- Dielectric Withstanding Voltage (DWV)Also known as voltage withstand or dielectric strength test, this measures a connector’s ability to withstand high voltage without breakdown. It involves applying a high voltage and observing if there’s any leakage current or dielectric breakdown.Example: For M12 connectors, the test voltage varies based on the number of pins, typically ranging from 0.5kVr.m.s. to 1.4kVr.m.s., with specific frequency requirements.

- Voltage DropVoltage drop is the reduction in voltage as current passes through a load, indicating the energy loss within a circuit. It should be within an acceptable range to ensure efficient power delivery.

- Temperature RiseTemperature rise refers to the increase in temperature of a product during operation. It’s a critical factor in evaluating the quality and safety of electrical products. Excessive temperature rise can degrade insulation materials and lead to hazards like electric shock, burns, or fire.

- Factors Affecting Temperature Rise:

- Contact Resistance: Lower contact resistance helps reduce temperature rise.

- Environmental Conditions: High ambient temperatures can increase contact resistance, thus raising temperature.

- Current Size: Higher currents typically result in greater temperature rise.

Testing Methods for Electrical Performance

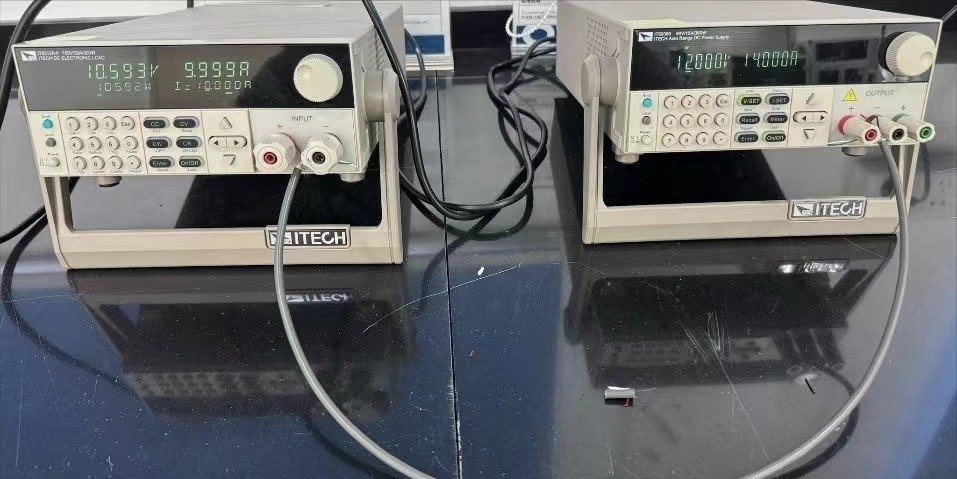

- Contact Resistance Testing:

- Test Voltage/Current: 20mV@100mA

- Standard Reference: EIA-364-23

- Insulation Resistance Testing:

- Parameters: DC voltage, voltage rise time, test duration, and minimum insulation resistance value.

- Standard Reference: EIA-364-21

- Dielectric Withstanding Voltage Testing:

- Parameters: Type and value of test voltage (AC/DC), voltage rise time, test duration, and criteria for breakdown or leakage current.

- Standard Reference: EIA-364-20

- Voltage Drop Testing:

- Parameters: Test current, test voltage, and duration.

- Standard Reference: USCAR21

- Temperature Rise Testing:

- Parameters: Type and value of test current (AC/DC), steady-state temperature definition, and test duration.

- Standard Reference: IEC 60512-5-1, UL 1977, UL 2238

Conclusion

Understanding and evaluating the electrical performance of connectors is crucial for ensuring their reliability and safety in various applications. By focusing on contact resistance, insulation resistance, dielectric withstanding voltage, voltage drop, and temperature rise, we can ensure connectors meet the required standards for optimal performance.

Leave a Reply